Study shows methods considered competent only 10 years ago can result in an unsafe repair today.

A research project carried out by KTI GmbH & Co in Germany shows that improperly repairing collision damage, especially in newer vehicles constructed with high tech materials, will lead to an unsafe vehicle in subsequent collisions. |

In a research paper presented in June at the 22nd International Technical Conference on the Enhanced Safety of Vehicles in Washington D.C., KTI detailed the results of its effort to objectively quantify the influence of non-professional repairs on the behavior of a car’s body structure in a subsequent crash.

|

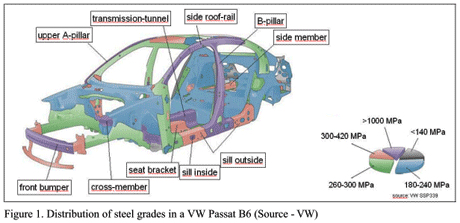

The body structure of late-model vehicles is typically made up of a number of modern steels, as seen in the diagram of this 2005 Passat. |

The Set Up

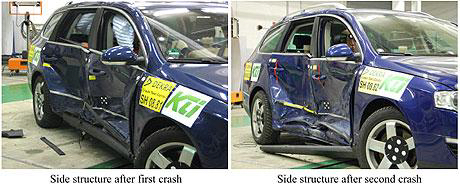

Following a first side impact crash of the original car using the Euro NCAP procedure, the repair of the damage caused by the first crash was carried out using traditional repair methods and older equipment that, today, would be considered a non-professional repair, no matter how competently those traditional repair methods may have been performed. Finally, differences in deformation behavior between the two crashes were analyzed to determine the implications for passenger safety. The Passat was chosen for the tests because its structure represented a state of the art car body with several high-strength and ultra high-strength steels with one of the highest torsional stiffness values (about 30,000 Nm/°) in its segment. Also, KTI said it chose to test the side of the car because only small changes in intrusion distance can present a higher risk for the occupants than in frontal or rear-end impacts at similar speed. The damaged car was repaired with an older spot welding machine with fixed pressure and 6.4 kA maximum current. For this repair, the OEM recommends an Inverter type welding machine with 10 kA maximum current and a variable pressure to join the high strength steel safely. The deformed inner sill, made from ultra high strength steel, was re-shaped and partially replaced on a bench then reinstalled using a MAG welding process. The OEM procedure calls for complete replacement of the B-Pillar and other deformed components constructed with high strength steel. Repairing these components is not acceptable because the structure and strength of the material is severely degraded by welding and reforming. |

The Results

|

Schedule Repairs

Let us know you are coming, so we can get you in and out.